Factory making 5kg Gas Atomization Equipment - Small Lab Type Gas Atomization Equipment – ShuangLing

Factory making 5kg Gas Atomization Equipment - Small Lab Type Gas Atomization Equipment – ShuangLing Detail:

Main Application

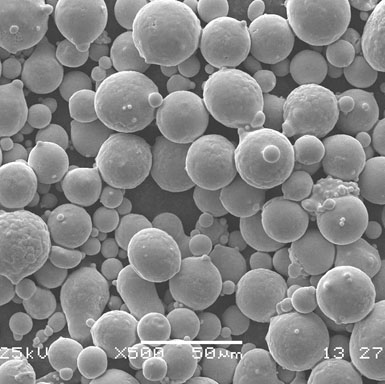

The equipment is used for making metal powders(or granulates) in atomization chamber after metal or metal alloy melted(in air or vacuum). It is widely used in university and scientific research institutions. The customer can choose high pressure gas atomization equipment or high pressure water atomization equipment according to different powder application.

The equipment is widely used in atomization additive manufacturing metal powder( 3D printing metal powder) and most of metal powder research or production in all institutes and universities.

This equipment is used for producing and researching various types of metal powder, such as a variety of stainless steel powder, alloy steel powder, copper powder, aluminum powder, silver powder, ceramic powder welding powder and so on.

For the capacity, 1-10kg capacity for choose according to customer’s requirement.

Equipment power is about 30-120KW.

Equipment size Length*Width*Height is 3.0M*3.0M*(3.5-6.5)M.

Product detail pictures:

Related Product Guide:

MasterChef Australia 100 step recipe made by Heston Blumenthal is now available | Electric Melting Furnace

Global Concrete Equipment Market | Forecast (2019-2025) – Schwing, Liebherr, GoughEngineering, Sicoma, KYB, IHI, Alliance | Champagne Gold Atomiser

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Factory making 5kg Gas Atomization Equipment - Small Lab Type Gas Atomization Equipment – ShuangLing , The product will supply to all over the world, such as: Jeddah , Czech , Madagascar , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!