Manufactur standard Laser Diffraction Particle Size Analysis - Crucible Rotation High Temperature Sintering Furnace – ShuangLing

Manufactur standard Laser Diffraction Particle Size Analysis - Crucible Rotation High Temperature Sintering Furnace – ShuangLing Detail:

This equipment is suitable for rotation sintering in high temperature under vacuum and protection atmosphere.

At present, most of the vacuum or gas protection sintering furnace is static sintering in the market, the temperature error is larger, and the materials will be heated uneven during high temperature sintering.

In recent years, many kinds materials high-temperature sintering has higher requirement for temperature uniformity during high temperature section, such as ultra-high temperature treatment of graphite, metal alloy sintering, tungsten and molybdenum materials sintering, metal powder sintering, rare earth material sintering, magnetic materials sintering, ceramic materials sintering, aerospace special materials sintering and so on.

Our company’s high-temperature furnace can achieve the materials in the furnace to be continuous dynamic sintered at high temperature, rotation speed can be frequency control, the max temperature can reach about 3000 centigrade.

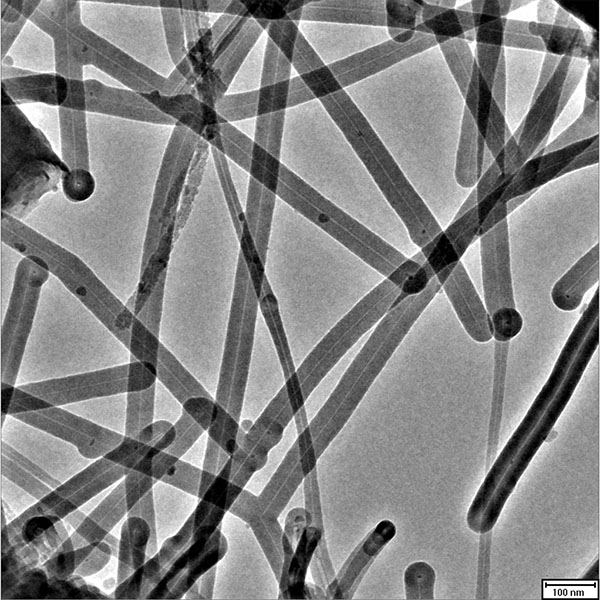

Product detail pictures:

Related Product Guide:

PyroGenesis Announces Closing of Second and Final Tranche of Non-Brokered Private Placement TSX Venture Exchange:PYR | Vacuum Induction Melting Furnace

How Long To Soak Bearings? – Fishing Rods, Reels, Line, and Knots | Vacuum Induction Melting Furnace

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Manufactur standard Laser Diffraction Particle Size Analysis - Crucible Rotation High Temperature Sintering Furnace – ShuangLing , The product will supply to all over the world, such as: kazakhstan , Colombia , Ecuador , Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!