OEM/ODM China Metal Powder Atomization Furnace - 3D Printing Metal Powder Atomization Equipment – ShuangLing

OEM/ODM China Metal Powder Atomization Furnace - 3D Printing Metal Powder Atomization Equipment – ShuangLing Detail:

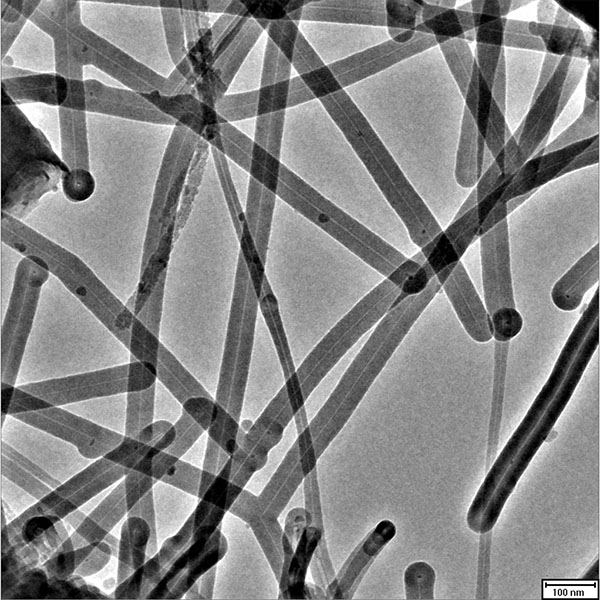

This equipment adopts high pressure gas atomization to make metal powder, the powder has many advantages like low oxygen content, small particle size, narrow particle size distribution, better spherical shape, high apparent density.

This equipment is suitable for all universities, institutes and companies to make researches or production 3D printing metal powder.

This equipment is suitable for production various types of powder such as a variety of stainless steel powder,high speed steel metal powdr, Co-Cr alloy powder, steel alloy powder, titanium alloy powder, copper powder, welding powder and so on.

Equipment capacity: 30-1000KG/batch

Equipment power: 120-1000KW

Equipment size L*W*H: 6.0m*6.0m*(6.0-10.0) m

3D Printing Metal Powder Atomization Equipment have obtained national invention patent and Hunan Province first set important technical equipment award.

Product detail pictures:

Related Product Guide:

Retech moving manufacturing jobs from Ukiah to Poland | Ultrasonic Emulsifying Equipment

Liberty House: Tata Steel UK sells its Specialty Steels business to Liberty House for £100 million | Champagne Gold Atomiser

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for OEM/ODM China Metal Powder Atomization Furnace - 3D Printing Metal Powder Atomization Equipment – ShuangLing , The product will supply to all over the world, such as: San Diego , Macedonia , Dubai , Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.