OEM/ODM Factory Vacuum Atomized Powder - Air Classifier for Metal Powder Atomiser System – ShuangLing

OEM/ODM Factory Vacuum Atomized Powder - Air Classifier for Metal Powder Atomiser System – ShuangLing Detail:

Applications of Air Classifiers:

Our air classifiers, which include self-diffluent classifiers and multi-stage classifiers, are mainly used to sort materials by the combination of particle size, density and shape, etc.; and also used to wipe off impurities in powder materials. Specifically, air separators can be used for separating coarse materials in submicron powders and nano-powders.

Classification for sticky, low-fluidity substances is also possible.

Common Features

1. Low energy consumption: Our air classifiers can save as much as 50% energy comparing to traditional vertical type or horizontal type classifiers.

2. High production efficiency: our air classifier combined the advantages of inertial classification technology and centrifugal classification technology.

3. High precision classification help guarantee that there is no oversize granularity and remains, etc. in finished products.

4. Longer service life: our air classifier has a low rotation speed while classifying materials in the same size, which help reduce the wear of impellers.

5. Full range of specifications: different air classifiers will be offered for your different needs.

6. Can be matched-use with wide variety of grinding mills, like ball mills, Raymond mills, impact mills or jet mills, etc.

7. Eco-friendly: No dust pollution for negative pressure production environment.

8. High automation gives a simple operation and stable performance.

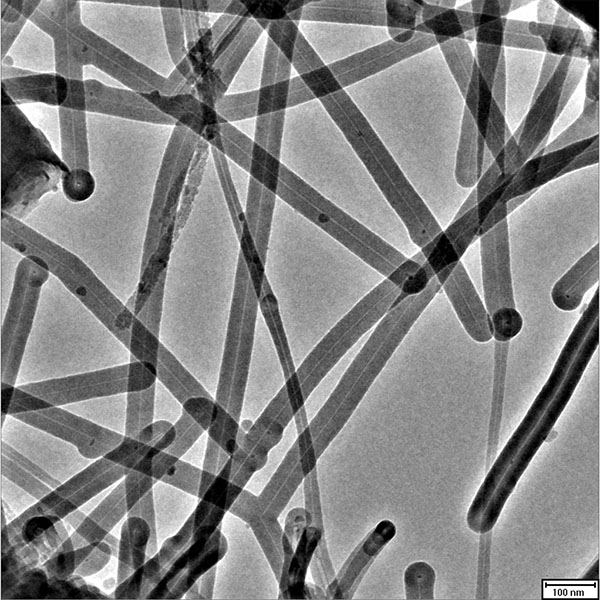

Product detail pictures:

Related Product Guide:

AMG Advanced Metallurgical Group N.V. (AMVMF) CEO Heinz Schimmelbusch on Q1 2019 Results | Vacuum Induction Melting Furnace

Brazing Consumables Market : Global Trends, Analysis and Forecast 2018 – 2028 | Electric Melting Furnace

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for OEM/ODM Factory Vacuum Atomized Powder - Air Classifier for Metal Powder Atomiser System – ShuangLing , The product will supply to all over the world, such as: Swaziland , Lithuania , Zurich , Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.