OEM/ODM Supplier Vacuum Gold Melting Induction Furnace - Crucible Rotation High Temperature Sintering Furnace – ShuangLing

OEM/ODM Supplier Vacuum Gold Melting Induction Furnace - Crucible Rotation High Temperature Sintering Furnace – ShuangLing Detail:

This equipment is suitable for rotation sintering in high temperature under vacuum and protection atmosphere.

At present, most of the vacuum or gas protection sintering furnace is static sintering in the market, the temperature error is larger, and the materials will be heated uneven during high temperature sintering.

In recent years, many kinds materials high-temperature sintering has higher requirement for temperature uniformity during high temperature section, such as ultra-high temperature treatment of graphite, metal alloy sintering, tungsten and molybdenum materials sintering, metal powder sintering, rare earth material sintering, magnetic materials sintering, ceramic materials sintering, aerospace special materials sintering and so on.

Our company’s high-temperature furnace can achieve the materials in the furnace to be continuous dynamic sintered at high temperature, rotation speed can be frequency control, the max temperature can reach about 3000 centigrade.

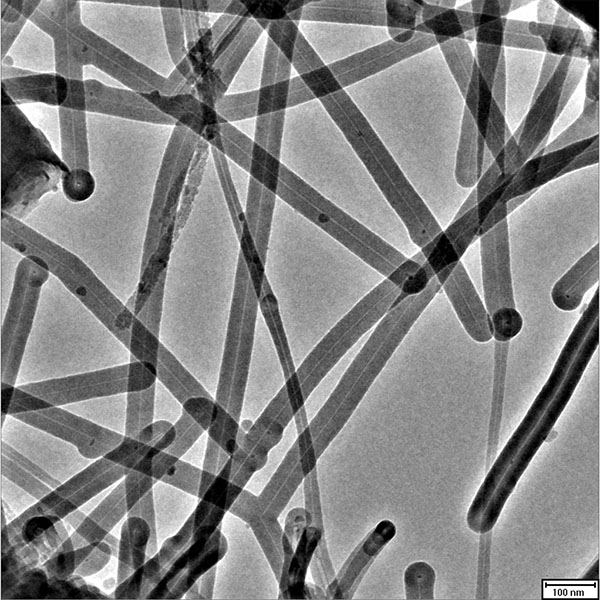

Product detail pictures:

Related Product Guide:

How North Korea Was Armed – Analysis | Vacuum Induction Melting Furnace

How Differences in Powder Density Impact 3D Printing Quality | Electric Melting Furnace

With our outstanding administration, powerful technical capability and strict top quality handle procedure, we go on to provide our purchasers with reliable good quality, reasonable selling prices and excellent services. We goal at becoming certainly one of your most responsible partners and earning your gratification for OEM/ODM Supplier Vacuum Gold Melting Induction Furnace - Crucible Rotation High Temperature Sintering Furnace – ShuangLing , The product will supply to all over the world, such as: Buenos Aires , Roman , Milan , We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.